Digital Fabric Printing NZ: Your Complete Industry Guide

Understanding Digital Fabric Printing Technology

Imagine trying to paint a detailed photograph onto a giant canvas with a regular paintbrush. Sounds tricky, right? Now, imagine printing that same photo, in perfect detail, onto fabric. That's essentially what digital fabric printing does in New Zealand. It takes us from the painstaking work of traditional methods to the pinpoint accuracy of modern technology. This allows for the kind of intricate detail and vibrant colours that were simply impossible before.

How Does It Work?

Think of your home printer, but supersized and designed specifically for fabric. You start with a digital design file, which is sent to a specialized printer. This printer uses inkjet technology to apply water-based inks directly onto the fabric. And just like your home printer needs different ink cartridges for different paper types, digital fabric printers use various inks formulated for different fabrics. This ensures the design bonds properly and won't wash away. Take a look at this image showing the different types of digital textile printing machines:

You can see how complex these machines are, precisely transforming digital designs into tangible prints on a variety of fabrics. It’s amazing to think that the same basic inkjet technology that prints our family photos is now used to create incredibly detailed textile designs. For more in-depth info, check out this article: Expert Custom Fabric Printing Techniques Create Unique Textiles.

Key Advantages of Digital Fabric Printing

Digital fabric printing isn't just a cool piece of technology; it offers some serious advantages for New Zealand businesses and designers:

- Detailed Designs: Imagine trying to reproduce a photograph with tiny brushstrokes. Digital printing captures those intricate details and subtle color gradients effortlessly.

- Faster Turnaround Times: Traditional fabric printing methods can be time-consuming. Digital printing cuts that time down significantly, getting your designs to market faster.

- On-Demand Production: Need just a few meters of a specific design? No problem. Digital printing lets you print exactly what you need, minimizing wasted material and storage costs. This is a huge plus for smaller businesses.

- Design Flexibility: Want to experiment with different colors or tweak a pattern? Digital printing gives you that freedom without the setup limitations of traditional screen printing.

These benefits are reshaping how we think about textile design and production. Businesses can now react quickly to trends and customer demands in a way they never could before. We'll delve deeper into how this impacts the New Zealand market in the following sections.

New Zealand's Digital Printing Revolution

The New Zealand textile scene is changing. Traditional methods are feeling the pressure, while innovative businesses are exploring the exciting world of digital fabric printing nz. This isn't a small, isolated shift. It's a larger movement changing how Kiwi companies approach design, manufacturing, and their role in the global market. We're seeing established textile companies adapting alongside nimble startups, all drawn in by the possibilities of digital technology.

This shift offers a unique opportunity for New Zealand. Our location, combined with a growing focus on sustainability, creates the perfect environment for digital fabric printing to thrive. It's a chance to build a new kind of textile industry – one that's competitive globally and kind to the planet. This section explores the market forces driving this change, looking at both the hurdles and the opportunities.

This move towards digital printing isn't just about fashion; it's affecting the whole printing sector. The traditional printing industry in New Zealand has actually seen a decline, with a compound annual growth rate (CAGR) of -5.4% from 2019 to 2024, reaching an estimated revenue of $1.3 billion in 2024. This downturn is partly because of the rise of digital alternatives, impacting different areas, including fashion. Discover more insights about New Zealand’s printing industry. This broader trend highlights the significant impact digital technology is having on long-standing industries and the possibilities it opens up for forward-thinking businesses.

Growth Potential and Market Timing

So, what does this mean for businesses thinking about investing in digital fabric printing in New Zealand? The timing is good for growth. There's increasing demand for personalized designs, quick turnaround times, and sustainable practices. Digital printing offers solutions for all of these, putting it in a strong position to grow in the next few years.

But, it's important to approach this strategically. Understanding the realities of the market, what investment is needed, and the potential challenges is key to long-term success. This isn't just about following a trend; it's about building sustainable businesses that contribute to New Zealand's economic and environmental future.

This means businesses considering digital fabric printing need to carefully evaluate their position. Is now the right time to invest? What are realistic growth expectations? By looking at businesses that have already made the successful switch to digital printing, we can gain valuable insights into what makes a difference in this evolving market. The following sections will dive into the details of how digital fabric printing works, its benefits for sustainability, and how to manage the transition effectively.

How Digital Fabric Printing Actually Works

Imagine explaining a smartphone camera to someone from the 1800s. That's the kind of leap we're talking about when comparing traditional screen printing to digital fabric printing in New Zealand. This section breaks down this technology into easy-to-understand concepts, from the specialized inks used to the precision engineering involved.

We'll explore various printing methods, comparing inkjet, dye-sublimation, and direct-to-garment printing. You’ll discover how digital files are transformed into physical textiles, what happens during the printing process, and why certain techniques work better for specific fabrics. This understanding will empower you to choose the best technology for your project, budget, and desired quality.

From Digital Design to Fabric Reality

The process starts with your digital design. This file is sent to a digital fabric printing machine, much like sending a document to your home printer. But these specialized printers are considerably larger and more complex, and they use inks specifically formulated for fabrics.

Different fabrics require different inks. This ensures the design bonds permanently and can withstand regular washing. Think of it like choosing the right paint for a particular surface – you wouldn't use exterior paint on an indoor wall.

Exploring the Technologies

Inkjet printing is a widely used method that sprays tiny droplets of ink onto the fabric. Picture a highly precise, controlled spray paint, building the design dot by dot.

Dye-sublimation, on the other hand, uses heat to transfer dye onto synthetic fabrics like polyester. The dye transforms into a gas and then solidifies within the fabric fibers. This creates vibrant, long-lasting prints that won't crack or peel.

Direct-to-garment (DTG) printing is similar to inkjet but specifically designed for printing directly onto finished garments, like t-shirts. It’s ideal for customized apparel and smaller production runs.

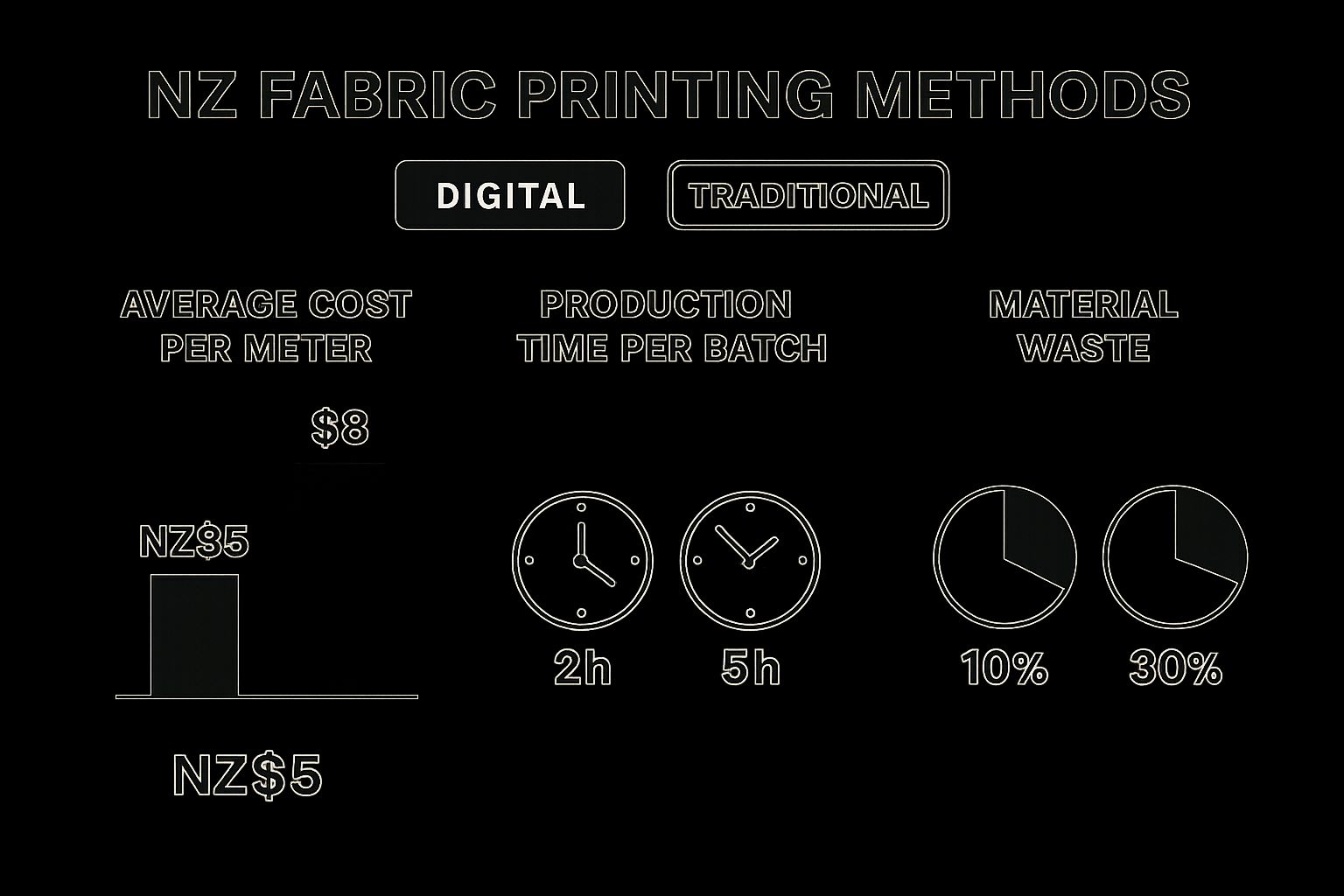

The infographic above compares digital and traditional fabric printing in New Zealand, looking at cost per meter, production time, and material waste. Digital printing offers significant advantages, as you can see.

Let's look at the numbers. Digital methods average NZ$5 per meter compared to NZ$8 for traditional methods. They also take only 2 hours per batch versus 5 hours for traditional printing. And perhaps most importantly, digital printing produces only 10% material waste compared to 30% for traditional methods. These efficiencies highlight the considerable benefits of switching to digital fabric printing.

Matching Technology to Fabric

Choosing the right technology depends on the fabric you're using and the desired outcome. For instance, dye-sublimation works best for polyester sportswear because of the vibrant colors and excellent durability it offers.

Inkjet printing is incredibly versatile and suitable for natural fibers like cotton and linen, making it ideal for home furnishings. DTG, as mentioned earlier, is perfect for small-batch custom apparel where intricate designs and personalized details are important.

Understanding these differences is key to achieving the best print quality and cost-effectiveness for your project. It will also equip you to make informed decisions when selecting a digital fabric printing provider in New Zealand.

To help illustrate the key differences between these technologies, let's take a look at this comparison table:

Digital Fabric Printing Technologies Comparison

This table compares different digital printing methods, their suitable fabric types, print quality, and typical applications. It also provides a general overview of the relative cost of each method.

| Technology | Suitable Fabrics | Print Quality | Best Applications | Cost Level |

|---|---|---|---|---|

| Inkjet | Cotton, linen, silk, some synthetics | High resolution, good color accuracy | Home furnishings, soft signage, fashion samples | Medium |

| Dye-Sublimation | Polyester, other synthetics | Vibrant, long-lasting, excellent color fastness | Sportswear, activewear, flags, banners | Medium |

| Direct-to-Garment (DTG) | Cotton, blends, finished garments | High detail, excellent for small runs | T-shirts, hoodies, personalized apparel | Medium-High |

As this table highlights, each digital printing method offers distinct advantages and is best suited for specific applications and fabric types. Choosing the right technology depends on the project's specific needs.

Sustainability Benefits For New Zealand Businesses

New Zealand has a well-earned reputation for environmental awareness. It's a value that resonates deeply within the culture. And it's a value that aligns perfectly with the sustainable advantages of digital fabric printing in New Zealand. This technology offers a real opportunity to lighten the environmental footprint of textile production, contributing to a cleaner, greener Aotearoa. Let's explore the key areas where digital printing minimizes its impact.

Reduced Water Usage: Protecting Our Waterways

Think about traditional fabric printing. It's like trying to fill a bathtub with a leaky bucket – vast amounts of water are needed for dyeing and washing. Digital fabric printing, however, is a whole different story. By applying ink directly to the fabric, it's like using a precise eyedropper, eliminating the need for those wasteful dye baths and endless rinsing. This water conservation is especially important in New Zealand, where protecting our precious resources is a top priority.

Eliminating Chemical Waste: A Breath of Fresh Air

Traditional textile dyeing often relies on harsh chemicals. Imagine the impact these chemicals have on our waterways and delicate ecosystems. Digital fabric printing offers a much cleaner approach, using eco-friendly, water-based inks that drastically minimize chemical waste. This shift towards cleaner production contributes to a healthier environment for all New Zealanders.

Minimizing Energy Consumption: Powering Down for a Greener Future

Traditional printing processes are energy-intensive. From running massive machinery to heating and drying fabrics, the energy demands quickly add up. Digital printing streamlines the process, reducing the need for extensive heating and drying. This lower energy consumption is vital for New Zealand businesses looking to lessen their environmental impact, especially with the increasing focus on reducing carbon emissions. Perhaps this topic sparks your interest in other sustainable fabrics like linen: Linen: A Sustainable Choice.

Sustainable Inks and Processes: Innovation for a Healthier Planet

The future of eco-friendly printing is bright, thanks to ongoing advancements in sustainable inks and printing processes. Some inks are now crafted from biodegradable materials, further reducing their long-term impact. New printing techniques are constantly being developed, requiring even less energy and water. It's like finding new ways to bake a cake using less flour and fewer eggs – getting the same delicious result with fewer resources.

Highlighting Environmental Credentials: A Winning Strategy

For New Zealand businesses, embracing sustainable practices isn't just about being environmentally responsible; it's also a smart business move. Today's consumers are increasingly conscious of the environmental cost of their purchases. They're looking for eco-friendly options. By adopting digital fabric printing, businesses can showcase their commitment to sustainability, attracting environmentally aware customers and strengthening their brand reputation. This focus on eco-friendly practices is a growing trend in New Zealand, offering a distinct advantage for businesses that embrace it. This discussion about sustainability naturally leads into the next topic: the exciting market growth and investment opportunities in digital fabric printing in New Zealand.

Let's take a closer look at the environmental advantages with a direct comparison:

To better illustrate the environmental advantages of digital fabric printing, let's examine a detailed comparison with traditional methods. The following table highlights key differences and similarities across several environmental factors relevant to New Zealand's unique context.

| Environmental Factor | Traditional Printing | Digital Printing | Improvement % | NZ Relevance |

|---|---|---|---|---|

| Water Usage | High (dyeing and washing) | Significantly Lower (direct ink application) | 70-90% | Crucial for water conservation efforts in NZ |

| Chemical Waste | High (dyes and fixing agents) | Low (eco-friendly, water-based inks) | 80-95% | Protects NZ waterways and ecosystems |

| Energy Consumption | High (machinery, heating, drying) | Lower (streamlined process) | 30-50% | Supports NZ's carbon emission reduction goals |

| Waste Generation | High (fabric scraps, excess ink) | Lower (precise ink application) | 20-40% | Reduces landfill waste and promotes circular economy in NZ |

| Air Pollution | Moderate (VOC emissions) | Low (reduced VOC emissions) | 50-70% | Improves air quality and public health in NZ |

As the table clearly shows, digital fabric printing offers substantial environmental benefits across the board. This makes it a particularly attractive option for New Zealand businesses committed to sustainability and environmental stewardship.

Market Growth and Investment Opportunities

Instead of trying to predict the future, let's look at the real market data and trends shaping digital fabric printing in New Zealand. These numbers tell a story of change and opportunity within our local market. We'll explore current growth projections, investment patterns, and how quickly businesses are adopting this technology, offering a glimpse into where this dynamic industry is headed.

Understanding the Numbers

While specific data for digital fabric printing in New Zealand is still somewhat limited, we can learn a lot by looking at the bigger picture. The overall digital printing market in New Zealand is expected to grow by 2.38% by 2027. This steady growth, combined with the global increase in digital fabric printing—fueled by technological advancements and a desire for personalized designs—is a positive sign. Discover more insights about this market growth. This growth isn't happening randomly; it's directly related to what consumers want and global trends.

This increasing demand for unique products and faster turnaround times creates the perfect environment for digital fabric printing to thrive. It's a technology built for these changing needs, offering both flexibility and speed. Imagine the rise of small, independent fashion labels in New Zealand, for example. Digital printing empowers them to create unique, small-batch collections without the huge upfront costs of traditional methods.

This allows them to compete and offer customers something truly special.

International Success Stories: Lessons for New Zealand

Looking beyond New Zealand, we can learn from what’s working (and what's not) in international markets. Analyzing these stories helps us understand realistic timelines, potential roadblocks, and reasonable growth expectations for digital fabric printing here. This knowledge is crucial for making informed decisions. For inspiration, take a look at this blog post: Trend Spotting: Linens & Velvets.

The rapid growth of digital fabric printing in the European fashion industry, for instance, provides valuable lessons. By studying their approach, we can identify best practices and avoid mistakes. This includes understanding the importance of investing in training to address the knowledge gap around this technology. It also highlights the need to build strong relationships with reliable printing providers.

Investing Wisely in Digital Fabric Printing

This section gives businesses thinking about entering or expanding in the digital fabric printing market a strong foundation. We'll explore key investment factors, discuss strategic timing, and offer practical advice from businesses that have successfully made this exciting transition. This isn't just about understanding the technology; it's about understanding the business world and making smart choices. The opportunities exist, but seizing them requires a strategic approach.

Overcoming Cost Barriers And Knowledge Gaps

Like any new venture, adopting digital fabric printing in New Zealand might seem daunting at first. Businesses naturally have questions about the initial investment and the time it takes to learn the ropes. Cost and complexity are common concerns. Let’s address these head-on with practical advice for Kiwi businesses.

Breaking Down the Costs

Let’s talk money. Yes, there's an initial investment in switching to digital fabric printing. But it’s important to look at the long game. Think of it like investing in solar panels for your home. The upfront cost is significant, but over time, the savings on your power bill make it worthwhile. Digital fabric printing offers similar long-term cost benefits.

One major advantage is reduced waste. Traditional printing methods often result in excess fabric and ink ending up in landfills. The precision of digital printing minimizes this, saving you money on materials and disposal. Plus, the faster turnaround times mean you can get products to market quicker and start generating revenue sooner.

Addressing Knowledge Gaps

Another common concern is the perceived learning curve. Many assume digital fabric printing is complex and requires specialized tech skills. But the truth is, the technology has become incredibly user-friendly. Think about how easy it is to use a smartphone today compared to those clunky early models.

Plenty of training resources and support services are available in New Zealand to help businesses transition smoothly. Many printing providers offer hands-on training and ongoing support to build your confidence.

Real-World Examples From New Zealand Businesses

The adoption of digital fabric printing in New Zealand's fashion industry has faced some hurdles, like cost concerns and a lack of information. Despite these challenges, designers have recognized the potential for creating unique, customized designs. However, uptake has been slower due to financial constraints and limited understanding of the benefits. You can learn more about these challenges here: Digital Fabric Printing Adoption in New Zealand.

Hearing from Kiwi businesses who've already made the switch to digital printing can be incredibly helpful. Their experiences offer valuable insights, highlighting real challenges and solutions. Many have found the transition smoother than expected, with the benefits—from cost savings to increased design flexibility—outweighing any initial hurdles.

Practical Transition Strategies

You don't have to dive headfirst into digital printing. Start small. Maybe incorporate it for a specific product line or for smaller production runs. This lets you learn the process and experience the advantages firsthand before fully committing.

Financing Options and Support

Several financing options are available in New Zealand to help businesses invest in digital printing equipment. Government grants and industry initiatives often offer financial support for sustainable business practices, making digital printing an even more attractive option.

Through education and strategic planning, the perceived barriers to digital fabric printing can become competitive advantages for New Zealand businesses. The next section will cover choosing the right printing provider—a crucial step for success in this exciting and growing market.

Choosing The Right Digital Printing Provider

Imagine you're looking for a business partner, not just a supplier. That's the mindset you need when selecting a digital fabric printing provider in New Zealand. This choice impacts everything from the final product's quality to delivery times and, ultimately, how happy your customers are. This guide helps you confidently explore your options, giving you practical ways to evaluate potential providers.

Key Questions to Ask Potential Providers

Finding the right printing partner requires careful thought. It's like building a house – you need the right foundation. Start by asking these key questions:

-

What printing technologies do they use? Do they specialize in inkjet printing, dye-sublimation, or direct-to-garment printing? Ensure their technology fits your fabric and design needs.

-

How do they control quality? How do they maintain consistent color and ensure the print lasts? Ask for samples and really look at them closely. Imagine holding your finished product – does the sample match your vision?

-

What about turnaround times and delivery? Can they meet your deadlines? Do they offer flexible shipping within New Zealand? Time is money, after all.

-

How do they price their services? Are there volume discounts? Any hidden fees? Transparency is key in a good partnership.

-

What kind of customer support do they offer? Will you have a dedicated contact? How quickly do they respond to questions or concerns? A responsive partner can save you headaches down the road.

Assessing Technical Capabilities and Service Reliability

Beyond the basic questions, you need to dig a little deeper. Think of it like checking the engine of a car before you buy it. Here's what to look for:

-

Experience and Expertise: How long have they been operating? What's their history with similar projects? Look for providers with a proven track record in the New Zealand market.

-

Technology and Equipment: Are they using modern, well-maintained equipment? Up-to-date technology shows they’re invested in quality and efficiency.

-

Software and Design Compatibility: Can they handle your design files? Are they comfortable with the design software you use? Smooth file transfers and compatibility are essential for a smooth workflow.

-

Certifications and Accreditations: Do they hold any relevant industry certifications, especially for quality or sustainability? These credentials provide reassurance and demonstrate a commitment to best practices.

Check out PrintNZ, a leading industry association in New Zealand:

PrintNZ offers resources and support for printing businesses in New Zealand, promoting best practices and industry standards. This resource can help you understand the printing services available in New Zealand and find reputable providers.

Real-World Examples and Successful Partnerships

Learning from others is always wise. Research successful partnerships between New Zealand businesses and digital fabric printing providers. What made those relationships click? What did they accomplish together? These stories offer practical insights to guide your decisions. For instance, successful partnerships often prioritize open communication, shared values, and a collaborative approach to problem-solving. These elements build strong, long-term relationships. Looking for decorating inspiration? Check out our guide on How to Decorate with Cushions.

Your Action Plan for Finding the Right Partner

-

Research and Shortlist: Create a list of potential providers based on your specific needs and priorities. Think of it like creating a guest list for a party - you want the right people there.

-

Request Quotes and Samples: Contact your shortlisted providers for detailed quotes and fabric samples. This lets you compare pricing, quality, and turnaround times side-by-side.

-

Check References: Ask for references and talk to their past clients. It's like getting reviews before buying a product.

-

Visit Their Facilities (If Possible): Seeing their printing setup firsthand gives you valuable insights into their capabilities and professionalism.

-

Negotiate and Finalize: Once you've chosen a provider, discuss the terms of your agreement and finalize the contract. It's the handshake that seals the deal.

Ready to update your living space with beautiful, custom-made textiles? Visit Maak Home today and browse our selection of high-quality, sustainable fabrics, cushions, curtains, and wallpapers, all carefully crafted in New Zealand.